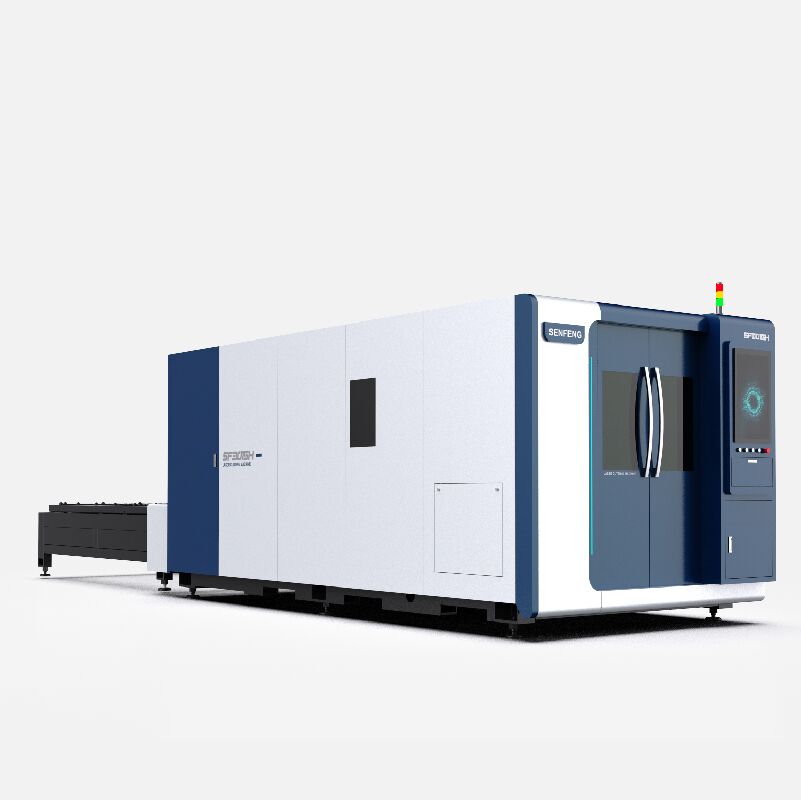

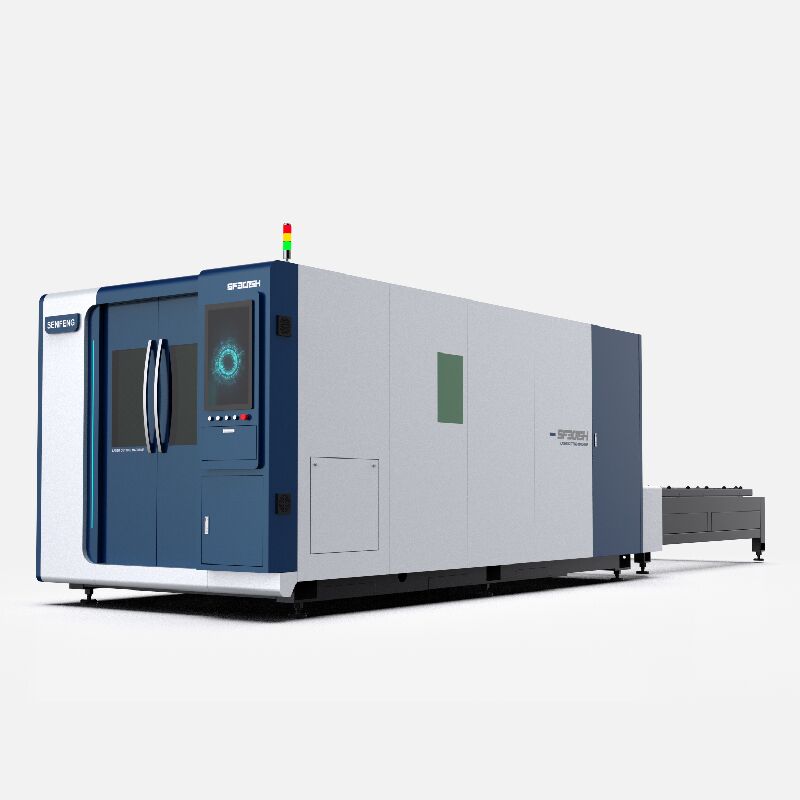

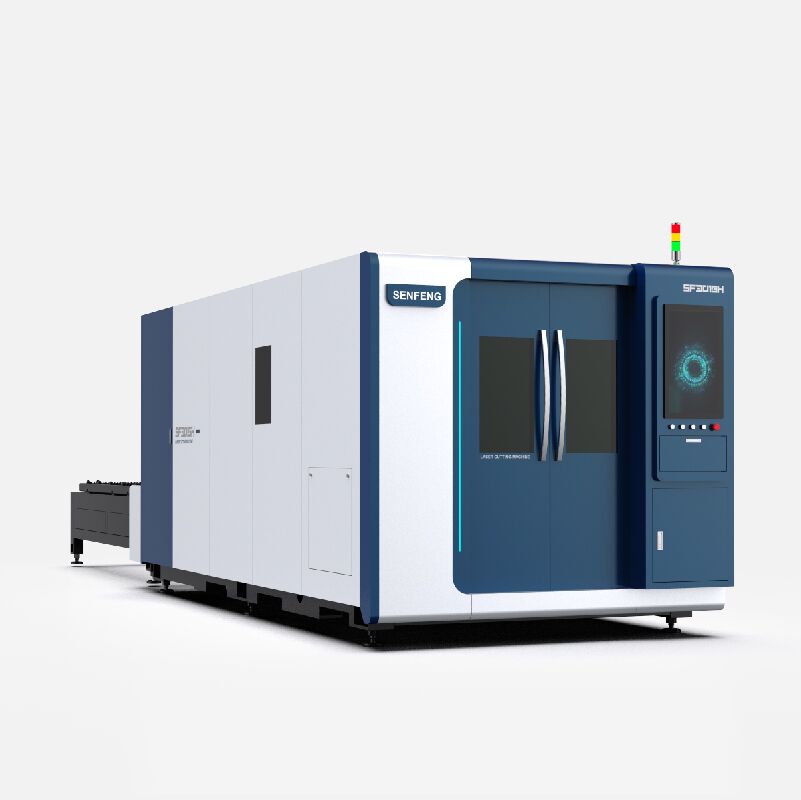

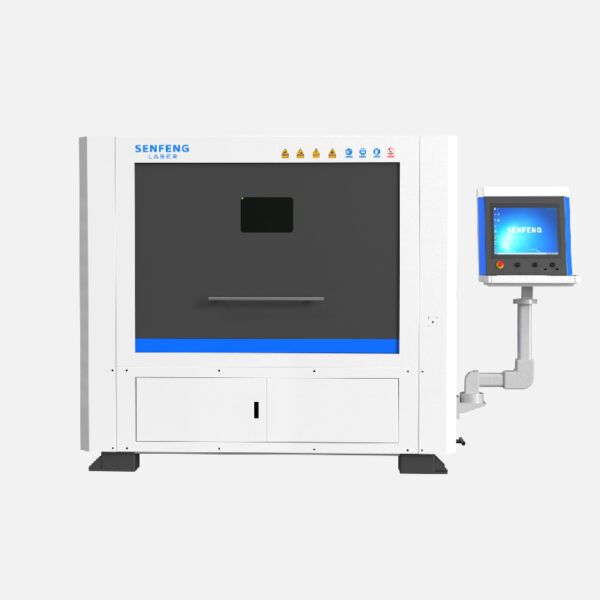

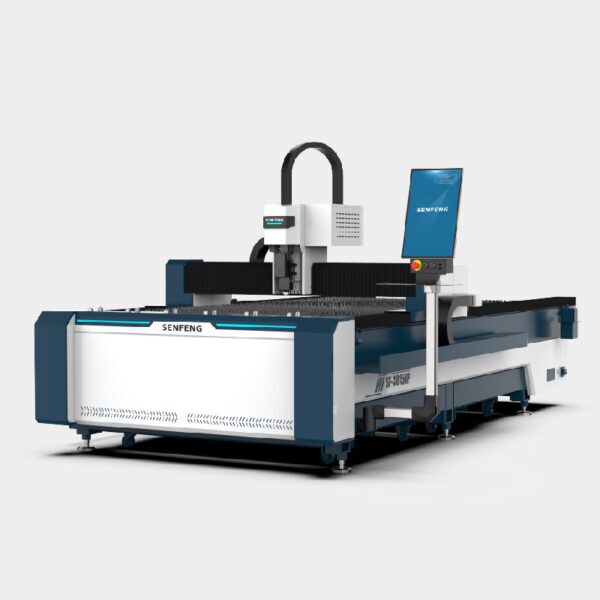

SF3015H fiber laser cutter is mainly designed for the power:1.5kw to 12kw, it is with full-protection cover, which can prevent laser radiation and protect worker safety, reduce environmental pollution; and it is also with auto-exchangeable platforms, which can save materials loading time, improve the processing efficiency. The exchange platform only takes 20 seconds to complete the exchange. The biggest feature of this machine is that the whole machine can fit into a 40HQ. No need frame container, which greatly saves freight costs. The sheet metal does not have to be dismantled for packing. It will save a lot of installation time.

Technical Parameters of Space Saver Fiber Laser Cutter SF3015H

| Model | Space Saver Fiber Laser Cutter SF3015H |

| Working Area | 10′ * 5′ |

| Laser Power | 1.5-12kW |

| X/Y Axis positioning accuracy | ±0.05mm |

| X/Y Axis repeated positioning accuracy | ±0.02mm |

| Max No-load Speed | 426′ /min |

| Max Load of Platforms | 700kg |

| Overall Dimensions | 335″ * 89″ * 86″ |

Advantages of Space Saver Fiber Laser Cutter SF3015H

1.Smaller Footprint, Wider Working Area

- The size of the machine is 335″ * 89″ * 86″, and the floor space is reduced by 22.2%.

- The whole machine can fit into a 40HQ.

- No need frame container, which saves freight cost.

2.Safe and Stable Operation

- 720° all-round safety inspection, follow up the cutting situation in time.

- Fully protected enclosed, reducing laser damage.

3.High Degree of Automation

- Autofocus Laser Head, improving positioning and cutting accuracy.

- Automatic gas distribution device for auxiliary gas.

Main Configuration of Space Saver Fiber Laser Cutter 12KW

1.High Strength Machine Bed

- Welded with high-quality steel plates and pipes.

- Annealing to eliminate internal stress

- sufficient structural stability and shock resistance

- Not deformed for a long time

2.Intelligent Surrounding Spiral Negative Pressure Partition Dust Removal System

- Intelligently switchingthe air outlet, time-sharing, partition, and sectional air exhaust

- Cooperating with the back-shaped sealing structure design at the bottom of the base to realize smokeless cutting.

3.Intelligent CNC Operating System

Adopt Cypcut numerical control system. With intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation and other features.What’s the Industry Application of Space Saver Fiber Laser Cutter 4KW?

The SF3015H fiber laser cutting machine is specialized for sheet metal processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, decorative advertising, etc.What does the Space Saver Fiber Laser Cutter cut?Carbon Steel, Stainless Steel, Aluminum Alloy, Brass, Copper, Galvanized Sheet, Silicon Steel Sheet, Electrolytic Sheet, Titanium Alloy, Manganese Alloy, etc.Cutting Samples

Five Star Fast Service System1.High efficiency

- 24 hours a day (mainly for international), 7 days a week, 365 days a year at any time to receive repair calls;

- Within 10 minutes, technical engineers will consult, fix maintenance plan in one hour, and send engineers in one working day.

2.After-sale service

- The seller provides one time free installation and training in buyer’s factory. Seller pays for the airplane tickets and salary for engineers, buyer should provide accommodation and food to engineers.

- The seller will provide technical guide’s e-mail, telephone, WeChat, WhatsApp and so on.

- The seller should pay for the travel expense if local service needed within warranty time.

3.Warranty

- The warranty of laser source is 2 years.

- The warranty of the machine is 2 years(main spare parts),except for the consumable parts such as ceramic ring, focus lens, nozzle etc. Warranty counts from the date marked on the label of the laser source and machine.

- Except the damage artificially, seller is responsible for offering the fittings free of charge during the warranty period.

4.Worry-free

- Pre-sale service: theoretical + practical operation training, self-diagnosis training for common faults, guidance for quick repair of difficult faults, and warning of matters needing attention in use;

- Regular service: regular maintenance reminder, regular door-to-door service, regular promotional activities;

- Value-added services: equipment software and hardware upgrading services, financial leasing services, delayed warranty service.

For more details, welcome to contact us! CLICK HERE!

Reviews

There are no reviews yet.