Introduction

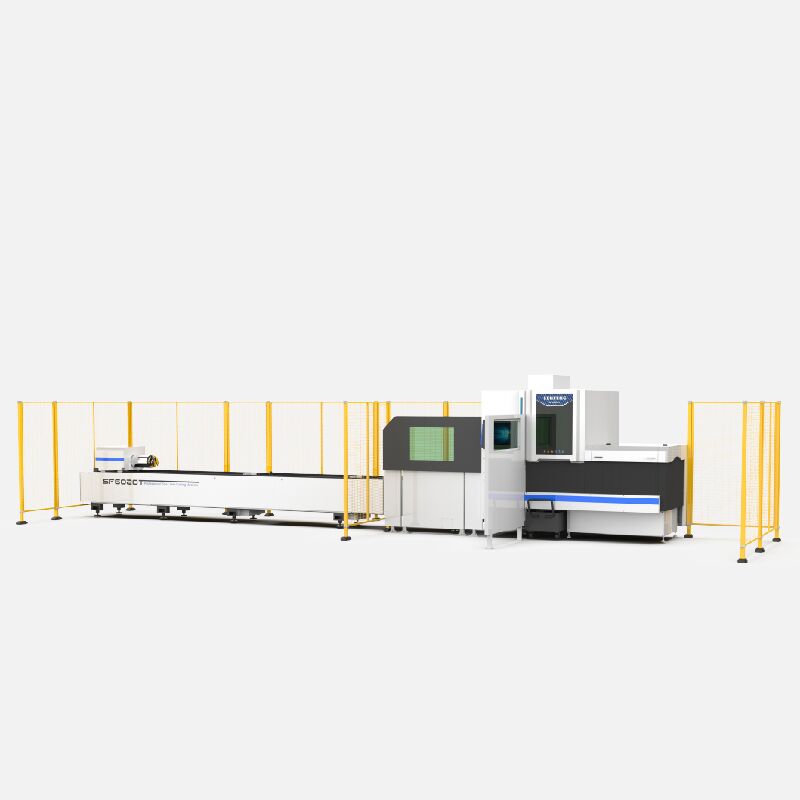

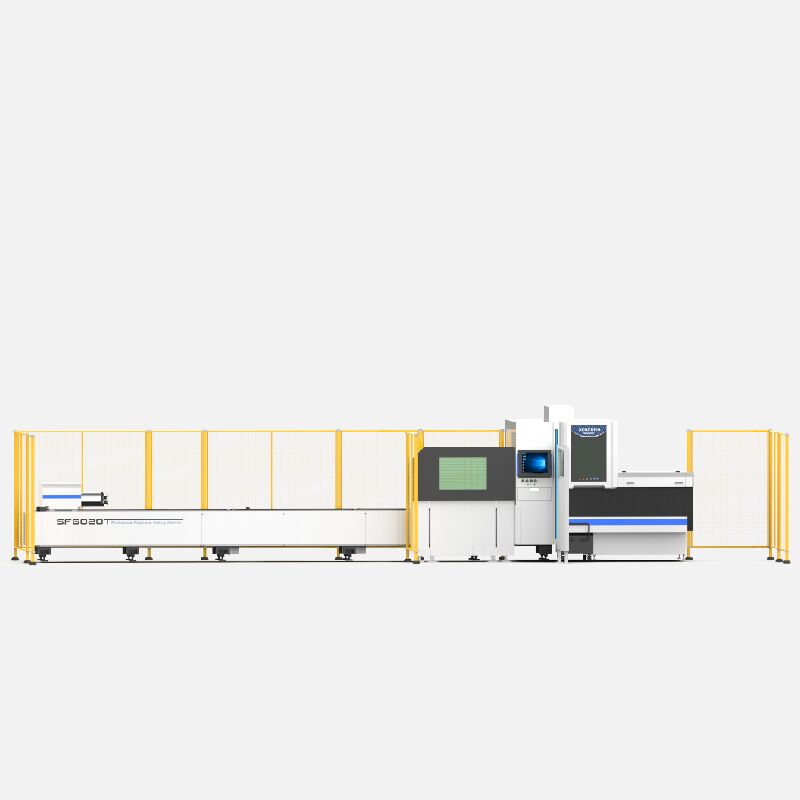

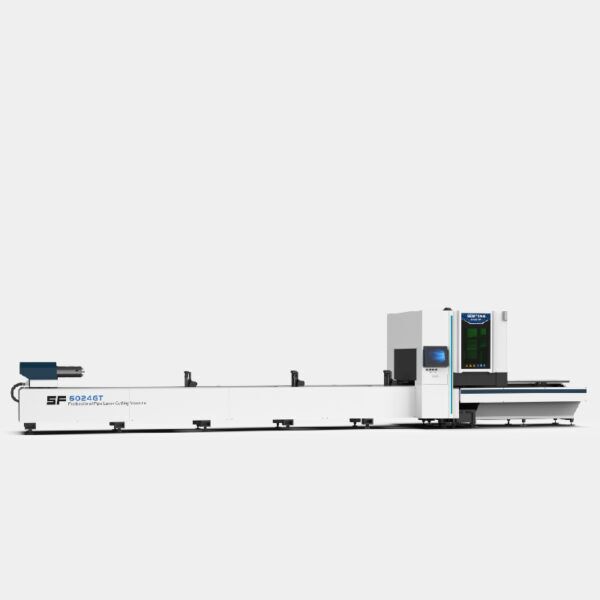

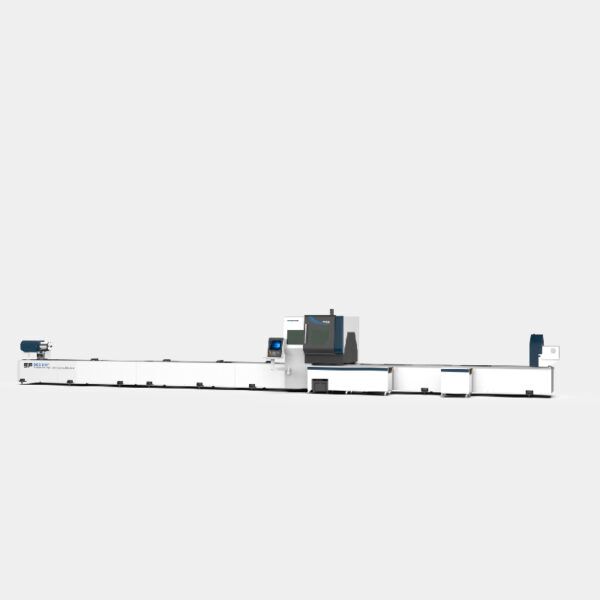

SF6020T Automatic metal tube laser cutter is also called tube laser cutting machine, which is used for cutting round tube,square tube,rectangular tube and other metal tube.Can cut round pipe with diameter <8.6 ” and square pipe with side length <5.9 “.SF6020T affordable metal tube laser cutter is equipped with fiber laser device, laser power from 1.5kw to 6kw.

Technical Parameters of Professional Pipe Laser Cutting Machine SF6020T

| Model | SF6020T |

| Pipe Processing Range | 20’* φ0.39″ ~8.66″ |

| Laser Power | 1.5KW/2KW/3KW/4KW/6KW |

| Maximum Speed | 262’/min |

| Maximum Rotational Speed | 100rpm |

| X/Y Axis positioning accuracy | ±0.05mm |

| X/Y Axis repeated positioning accuracy | ±0.03mm |

Advantages of Professional Pipe Laser Cutting Machine SF6020T

1.Automatic Loading

Through the numerical control system to realize the loading and unloading, automatic collection of finished products and materials, saving labor costs and improving cutting efficiency.

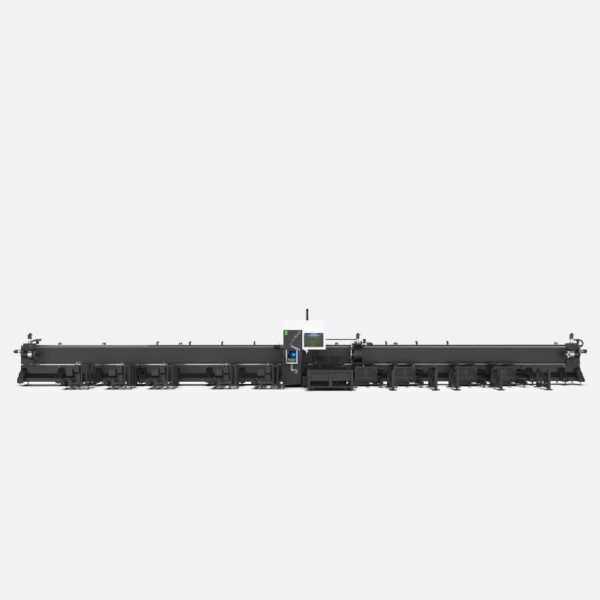

2.Floating Support

The unique V-shaped and parallel follow-up support function overcomes the drooping and swing of the workpiece to ensure long tube cutting accuracy.

3.HoneycombCarbon Structure

After high temperature annealing treatment, using precision welding process whole welding, with high strength and stability.

What’s the Industry Application of Professional Pipe Laser Cutting Machine SF6020T

Laser pipe cutter is applied in rail transit, automobile, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, Kitchenware and bathroom, decorative advertising, laser processing services and other machinery manufacturing and processing industries.

What does the Professional Pipe Laser Cutting Machine SF6020T cut?

Support round pipe, square pipe, U – shaped pipe, rectangular pipe and other different shapes of pipe. Adopt the special pipe cutting system, realized the layout of parts, common side, build-up welding cutting and other special processing.

Five Star Fast Service System1.High efficiency

- 24 hours a day (mainly for international), 7 days a week, 365 days a year at any time to receive repair calls;

- Within 10 minutes, technical engineers will consult, fix maintenance plan in one hour, and send engineers in one working day.

2.After-sale service

- The seller provides one time free installation and training in buyer’s factory. Seller pays for the airplane tickets and salary for engineers, buyer should provide accommodation and food to engineers.

- The seller will provide technical guide’s e-mail, telephone, WeChat, WhatsApp and so on.

- The seller should pay for the travel expense if local service needed within warranty time.

3.Warranty

- The warranty of the machine is 2 years(main spare parts),except for the consumable parts such as ceramic ring, focus lens, nozzle etc. Warranty counts from the date marked on the label of the laser source and machine.

- Except the damage artificially, seller is responsible for offering the fittings free of charge during the warranty period.

4.Worry-free

- Pre-sale service: theoretical + practical operation training, self-diagnosis training for common faults, guidance for quick repair of difficult faults, and warning of matters needing attention in use;

- Regular service: regular maintenance reminder, regular door-to-door service, regular promotional activities;

- Value-added services: equipment software and hardware upgrading services, financial leasing services, delayed warranty service.

For more details, welcome to contact us! CLICK HERE!

Reviews

There are no reviews yet.