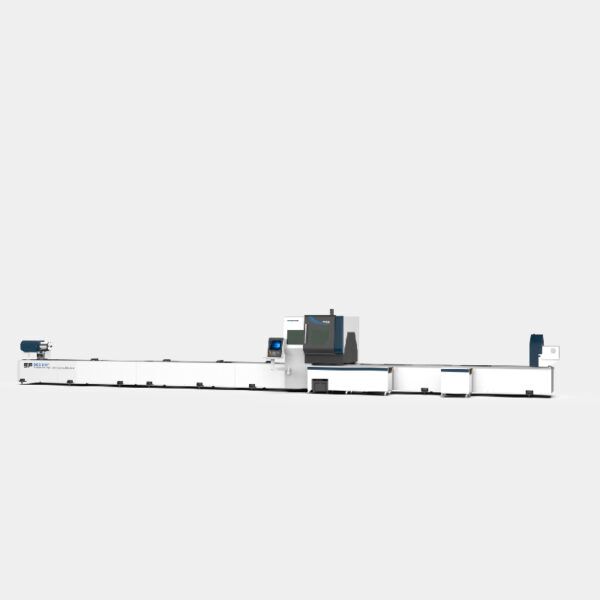

Three full-stroke chucks can correct tube deformation to make cutting precision high and detect tube position in real time. Due to 7-axis linkage, zero tailing is made possible to maximize material utilization.

- Max load: 2000kg

- Max clamping length: 472.44″

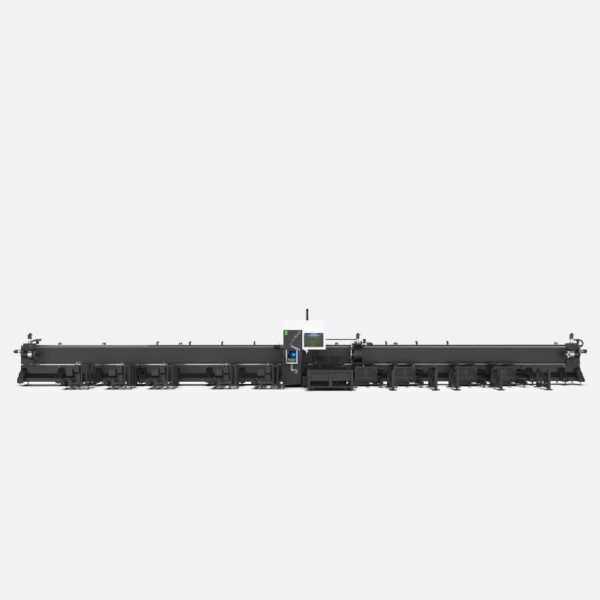

The servo-controlled devices may adjust tube support height and make tube and chucks center coaxial according to tube size. No impact on machine body while cutting heavy tubes.

- Follow-up support with no tube sagging

- Sectional structure to fit for tubes of different lengths

With optimal algorithms, this automatic nesting software can nest tubes as much as possible. Users are entitled to change cutting order and optimize cutting path to reduce waste and maximize tube utilization.

- Automatic programming

- High-efficient nesting

- A wealth of typesetting modes

Its triangular structure is featured by high stability, large load capacity and good vibration reducing performance after going through fine welding, annealing stress relief, secondary aging treatment and precision finishing.

- Three sections

Spliced together for easy replacement as needed

- Lifting holes

Facilitate to move and save transport costs

With right-angled cutting head, swing angle will be accurately controlled and gas flow output is monitored in real time. In doing so, the gas flow can center on metal surface to make cutting section better.

- Autofocus

- Auto obstacle avoidance

- Smart temperature/gas leakage detection

| Model | SF9035ST | SF12035ST | SF12050ST |

| Laser Power | 6-20kW | 6-20kW | 6-20kW |

| Max Length of Tube | 354.33″ | 472.44″ | 472.44″ |

| Scope of Tube Size | Φ0.79″~14.17″ | Φ1.97″~14.17″ | Φ1.97″~500 |

| □0.79″*0.79″~14.17″*14.17″ | □1.97″*1.97″~14.17″*14.17″ | □1.97″*1.97″~19.69″*19.69″ | |

| Max Weight of Tube | 1200kg | 1200kg | 2000kg |

| X/Y-axis Positioning Accuracy | ±0.05mm/m | ±0.1/10000mm/m | ±0.1/10000mm/m |

| X/Y-axis Repositioning Accuracy | ±0.03mm | ±0.05mm | ±0.05mm |

| Max No-load Speed | 196’/min | 196’/min | 131’/min |

| Max Rotating Speed of Chucks | 60r/min | 60r/min | 40r/min |

| Overall Dimensions | 708.66″*275.59″*177.17″ | 846.46″*275.59″*177.17″ | 866.14″*283.46″*163.39 |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | ||

HERE ARE YOUR ANSWERS

Free on-site Demo

Contact the showroom in advance and come

to SENFENG to enjoy silky cutting at any time.

Call or Chat

Don’t know how to solve the problem you encounter?

We are always here!

Call (562) 319 8053

Reviews

There are no reviews yet.