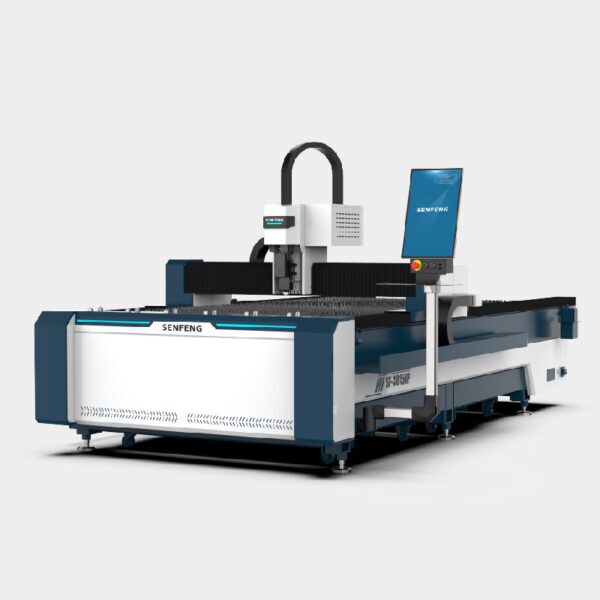

The control system, chucks, cutting head, machine body and self-developed laser generator are well adapted with each other, so as to cut small tube without overburning or adhering slag and large tube fleetly.

- No-load speed: 196.85′-492.13′

- Acceleration: 120kg-500kg

Based on EtherCAT protocol, it is easy for the system to get started only by clicking a button. Its built-in nesting software can nest both single or multiple parts, and import files of different formats in batch.

* Content-rich cutting database * Co-edge cutting

* Automatic centering * Corner cutting

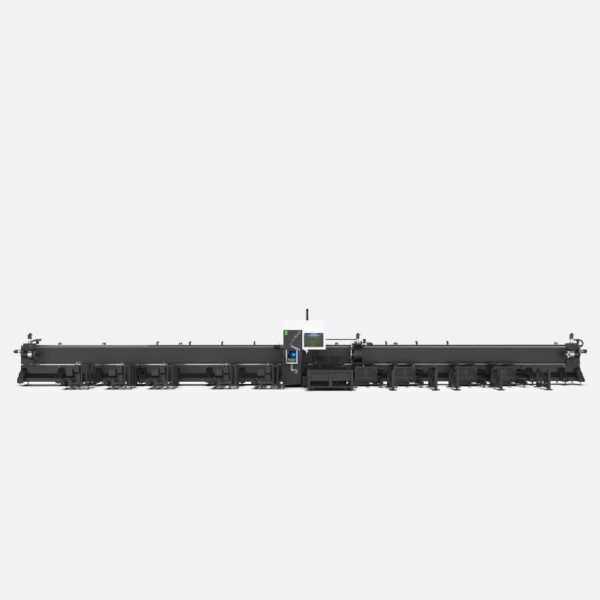

The machine comes standard with automatic unloading device to unload 3m long tube. Users may apply for semi-/fully-automatic loading devices as optional accessories, so as to reduce labor intensity during work.

The chucks are self-centering and high in clamping precision. Pneumatic grippers are adopted to clamp tubes of different shapes, sizes and weights firmly.

- Rotating speed: 60-180r/min

We offer two kinds of tube support modes. For follow-up support, it usually moves along with rotating tube. In case of vari-pitch support, long tube will be free from cutting deviation caused by its swing up and down.

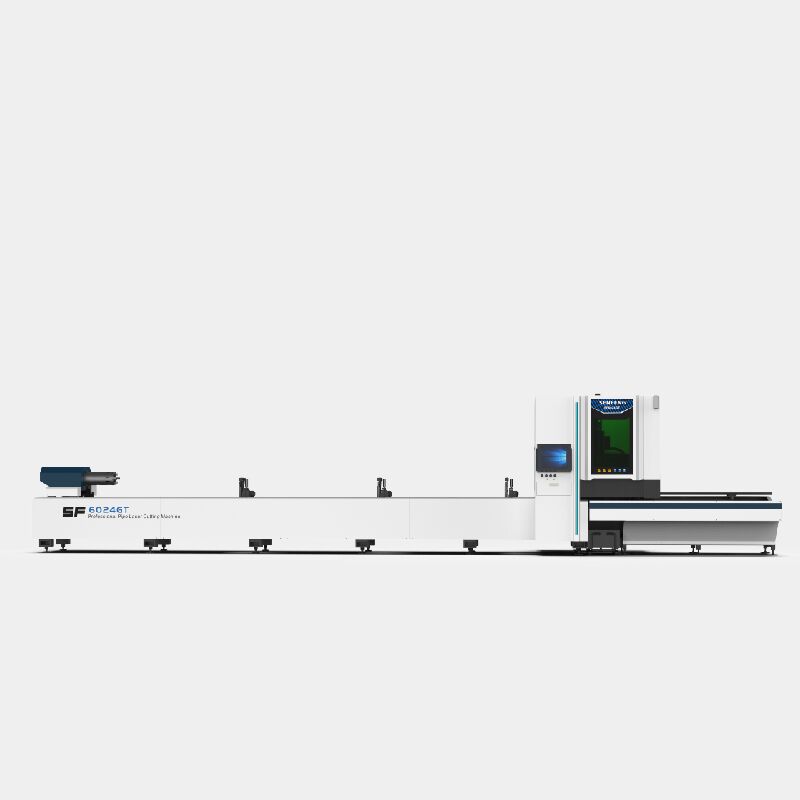

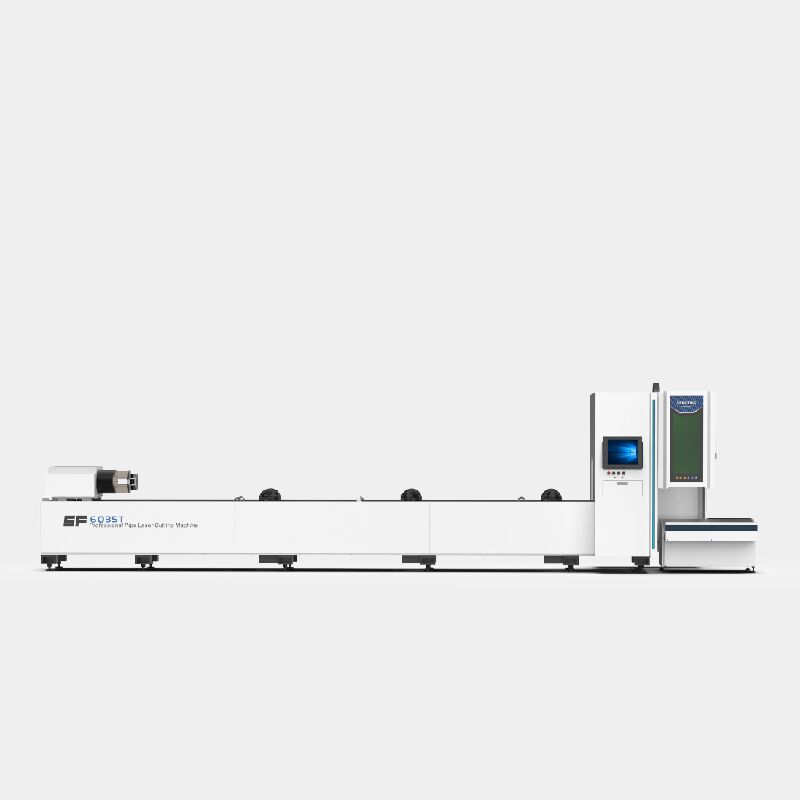

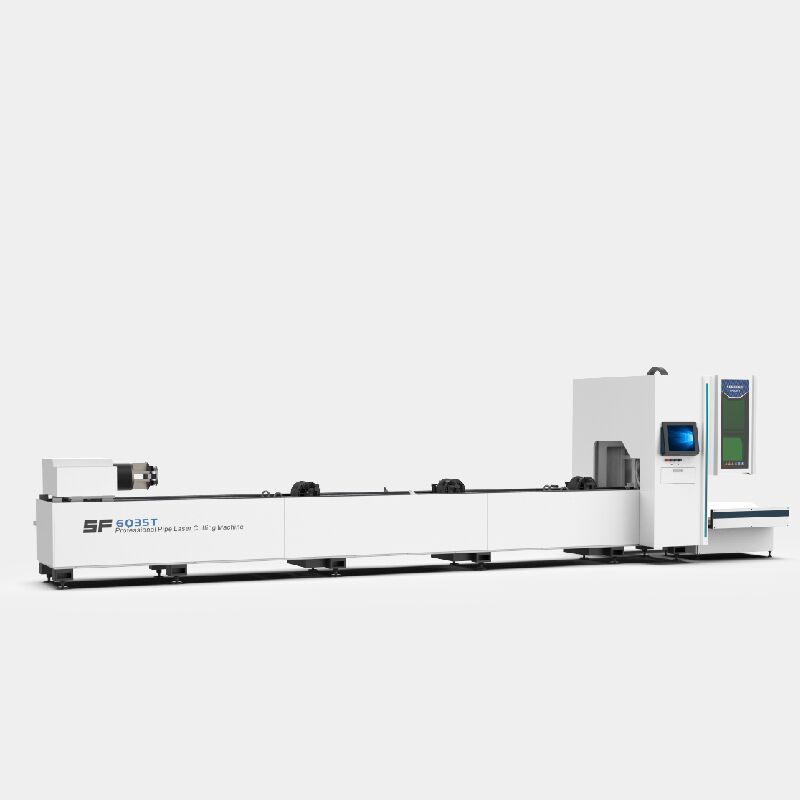

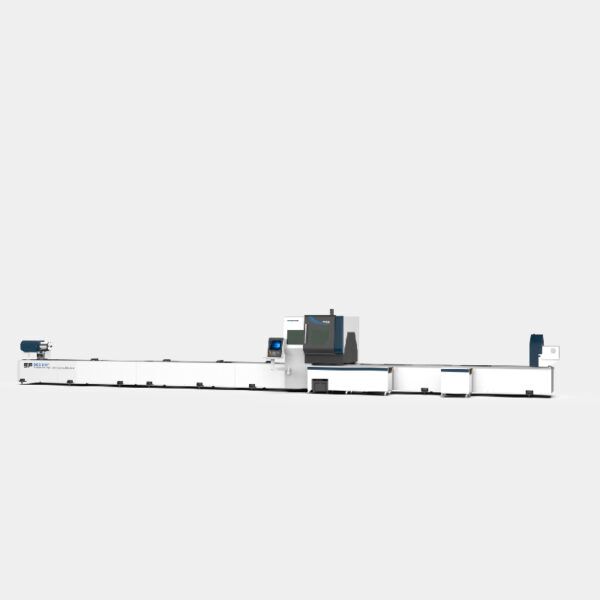

| Model | SF6012T | SF6016T | SF6020T | SF6024T | SF6035T |

| Laser Power | 1.5-3kW | 1.5-3kW | 1.5-6kW | 1.5-6kW | 1.5-6kW |

| Max Length of Tube | 19.69′ | 19.69′ | 19.69′ | 19.69′ | 19.69′ |

| Scope of Tube Size (mm) | Φ0.32″~4.72″ | Φ0.39″~6.30″ | Φ0.39″~8.66″ | Φ0.39″~9.06″ | Φ0.79″~14.17″ |

| □0.32″*0.32″~4.72″*4.72″ | □0.39″*0.39″~6.30″*6.30″ | □0.39″*0.39″~5.91″*5.91″ | □0.39″*0.39″~9.06″*9.06″ | □0.79″*0.79″~14.17″*14.17″ | |

| Max Weight of Tube | 120kg | 160kg | 200kg | 250kg | 500kg |

| X/Y-axis Positioning Accuracy | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.03mm | ±0.03mm |

| Max No-load Speed | 492.13’/min | 360.89’/min | 328.08’/min | 328.08’/min | 196.85’/min |

| Max Rotating Speed of Chucks | 180r/min | 140r/min | 100r/min | 100r/min | 60r/min |

HERE ARE YOUR ANSWERS

Free on-site Demo

Contact the showroom in advance and come

to SENFENG to enjoy silky cutting at any time.

Call or Chat

Don’t know how to solve the problem you encounter?

We are always here!

Call (562) 319 8053

Reviews

There are no reviews yet.