Metal Cutting

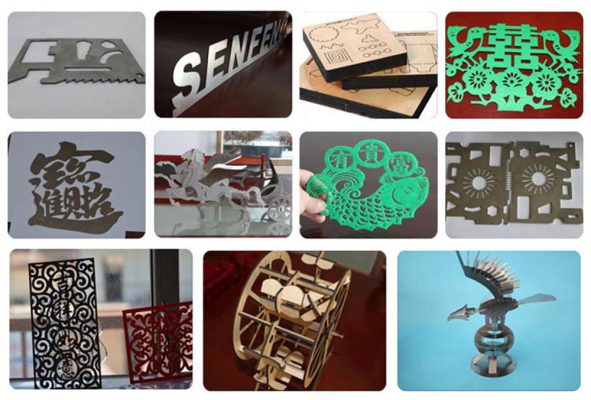

Lasers have brought heavy-duty & precision metal cutting to fabrication shops both large and small, helping even smaller businesses with confined spaces achieve a finished product that matches the refinement of the largest heavy-duty manufacturers. Not only can Lasers help fabrication shops achieve a level of precision that was vastly more difficult & expensive before, but they also help scale-up to meet demand, as they are much faster than other types of metal cutters.

Before, working with heavy duty metals (stainless, carbon, or galvanized steel, cooper, brass, etc) was the realm of large manufacturers, but Fiber Lasers have allowed advanced metal cutting to be attained by anyone familiar with Computer Aided Design with a facility large enough to hold a single machine. Fiber Lasers are faster than waterjets, and more exact than CNC routers or flamecutters, and have more versatile ability to be configured to custom designs.

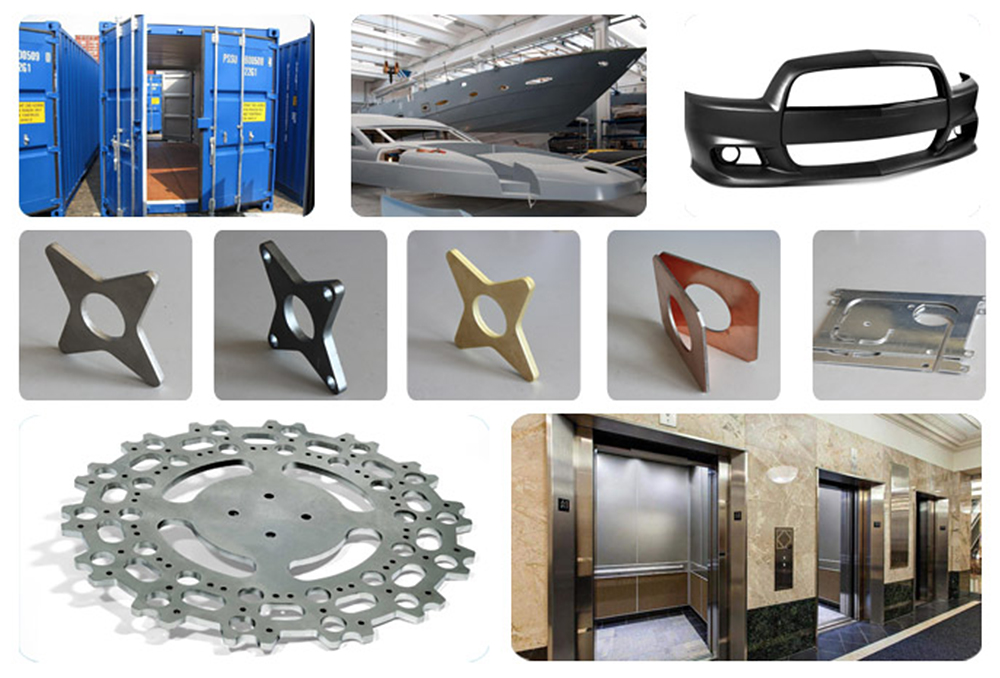

Beyond metal work for craft & commercial use, our Lasers can be used for all types of factory applications, creating parts for advanced machines (heavy industry, automotive or aerospace parts, etc), household appliances & electronics, or cutting sheet metal. While CO2 lasers can cut certain types of thin steel, Fiber Lasers are primarily used for metal because they can cut other metals as well (aluminum, copper, brass, etc), and can cut thicker metals than CO2 Lasers can. Fiber Lasers also use less power when cutting metal and require less maintenance/down-time.

https://www.senfenglaserusa.com/product-tag/metal-laser-cutter/

We welcome you to come to our Demo Center (in Commerce, CA) to try out your own designs, materials, and industrial specifications. Our technicians can easily review the versatile uses and finer-points of using laser technology to help you better weigh your upgrading options, and see for yourself if Fiber Laser is the technology that will help you scale-up your business to meet the volume & precision demands of your future orders.