Laser cutting has drastically changed the modern manufacturing industry recently, in particular industries needing to cut steels and other metals at high precision. As demands for cutting efficiency and quality are increasing, China has developed into a world-leading manufacturer in the sector of laser cutting.

I. Why Laser Cutting Tables for Steel are Important

Laser cutting tables for steel are of great importance to modern metal fabrication because of their high ability to cut steel sheets at fast speed and with wide range of applications. They adopt the focused laser beams to melt, burn or vaporize the steel materials, so as to provide clean cutting with the least waste. Their high precision helps to realize intricate designs and high-quality finishes, making them a good choice for industries like automobile, aerospace and manufacturing.

II. SENFENG’s Top Selling Laser Cutting Tables in 2025

SENFENG Laser is a major player in Chinese laser cutting table market. With quality machines and advanced technology, SENFENG can offer high-quality machines that give consideration to high precision and quality. Here are our models that are expected to be top sellers in 2025.

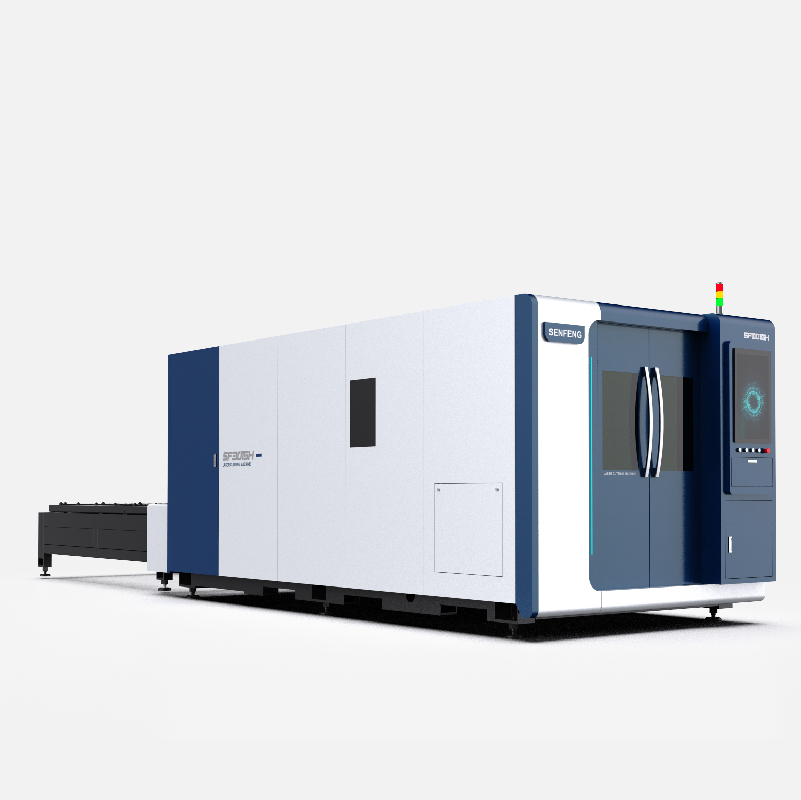

This classic model has upgraded its appearance and functions time after time according to market feedback at home and abroad. It has high cost performance and is outfitted with protective chamber and double exchange platforms, but its compact size can satisfy some customers who prefer to high power but lack of space.

* Cut thin steel sheet at lightning-fast speed

In our self-developed CNC system, the fly cutting, obstacle avoidance at idling as well as leapfrog of cutting head are provided. In addition to instant response, it also balances intelligence, efficiency and safety well.

* Stand out in dynamic performance

The beam is made of aviation-grade AL alloy withstanding extrusion forming, quenching thermal aging and finish machining. It gets lighter in weight, higher in rigidity and toughness. Owing to finite element analysis, ideal dynamic performance can coexist with fast moving.

* Speed up your production

On double exchange platforms, the cutting, loading and unloading run in parallel. With that, waiting time for loading or unloading will be greatly reduced to link up with following procedures. So, work speed will be multiplied.

* Fast to remove smoke and dust

To enable smoke-free effects, intelligent negative-pressure dust removal system works with bottom U-shaped sealing structure to control air vents according to cutting position in real time.

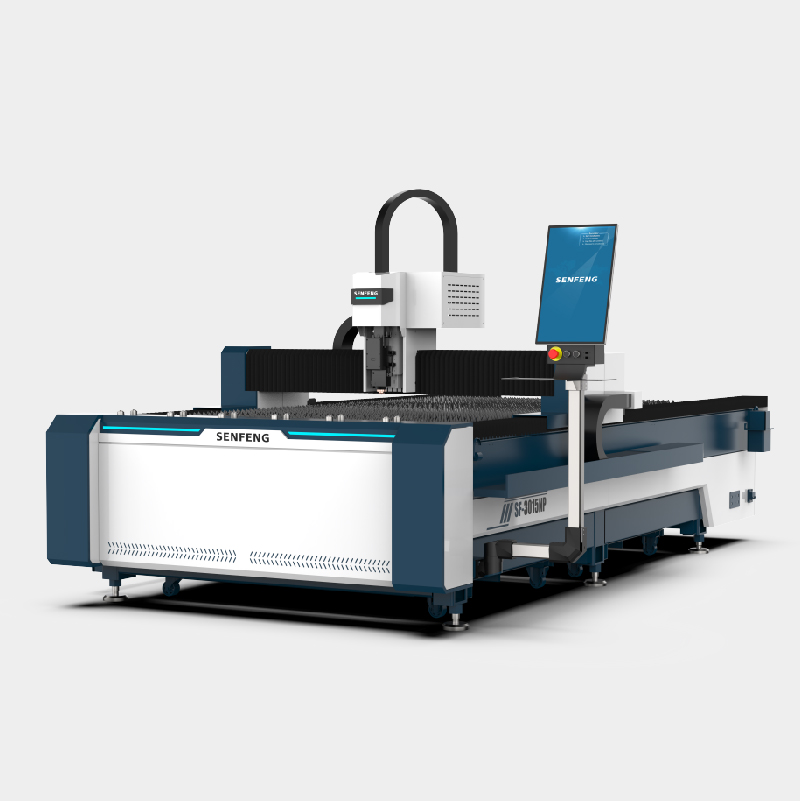

This machine is used to cut medium-thin steel sheet. It has open-style structure and offers two different configurations. A 40HQ container can accommodate 6 sets of 3015NP at much less freights.

* Intelligent control system

We adopt intelligent bus-based CNC system (with 21.5-inch touch screen). It is easy to install and debug, featured by fast data transmission, low failure rate and easy maintenance.

* Multiply cutting speed

Its moving motor, with the latest locking structure, makes sure of perfect dynamic performance at high movement, in this way, the machine can cut steel sheets into various shapes.

* Fast to exhaust smoke

There are double ventilating ducts that are available to speed up air ventilation and make smoke exhaust better together with air inlet & outlet. So, your workshop will become much cleaner.

* Save oversea freights

A 40HQ container can hold 6 sets of 3015NP, which provides a new option for bulk ordering customers and sharply reduces oversea shipment costs.

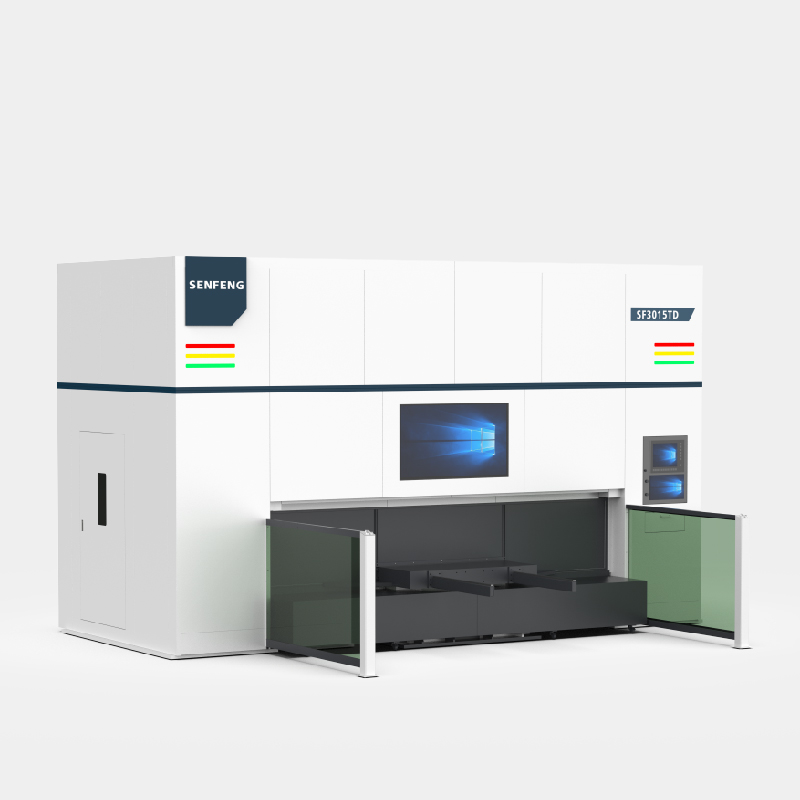

- TX Series Ultra-large Beveling Laser Metal Cutting Table

This large-sized machine can enable both straight cut and beveling. Its modular body may be tailored in terms of length and width, in order to cut ultra-long (≥6000mm) and super-heavy plate. Besides, its standard-compliant beveling contributes to making later welding firm enough.

* Cut ±45° bevel

High-power autofocus laser cutting head can not only cut with 0° straight section, but also enable ±45° beveling in X, Y, V and other shapes, for the convenience of seamless welding and splicing.

* Cut super metal sheets for steel

We adopt the spliced ground-rack hollow machine tool to increase carrying capacity. It will not vibrate while cutting ultra-large or super-heavy sheet, incl. extra-heavy sheet (max load of its single platform: 47T), super-thick sheet (cut 80mm thick sheet stably and 200mm at extreme at 60kW power) and extra-large sheet (3-5m width and 6-30m length available).

* Safety light curtain

With it, machine tool will stop instantly when anyone keeps too close to beam, as to to protect both man and machine.

* Intelligent 3D five-axis CNC system

It is bus-based and adopts follow-up control to fight off the effect of sheet unevenness. With memory cache and content-rich cutting database, users are allowed to use all stored parameters at will.

This machine is specially designed for automobile and aimed at drilling and trimming 3D hot-forming metal workpieces. As thus, automobile will be more light-weight and extend its endurance mileage.

* Deal with 3D complex-shaped curved parts

Unlike the tradition, this model can cut workpieces of different shape only by changing its internal procedures, without need to replace dies. In case of mass production, workpieces will be cut at constant quality after one-time programming.

* Intelligent CNC system

We adopt a top-end 3D five-axis control system to take follow-up control of cutting height, just fighting off the effect of multi-pointed and uneven 3D workpiece on cutting effects.

* Cut at high precision

We adopt small and light-weight 3D five-axis cutting head, with high dynamics. It can rotate from one to another plane rapidly but doesn’t change its focal spot. As thus, its cutting precision is above common standards.

* Dual-station rotary platforms

They can carry workpieces to one station and then rotates for 180° flexibly to convey the finished parts outside the machine for further transfer or change.

III. Trends Shaping Laser Cutting Tables in 2025

- Work with Industry 4.0

Recently, the Laser cutting tables are becoming much smarter, so that manufacturers can adopt Industry 4.0 such as IoT connectivity and AI-based diagnostics. These allow them to monitor machine status in real time, optimize working schedules, and predict maintenance needs, reducing possible downtime.

- Allow for customization

As demands for personalized solutions are growing, more and more manufacturers are offering tailored laser cutting tables to adapt to different requirements of steel fabrication. These features may include different bed sizes, laser powers and additional modules for specialized tasks.

- Pay more attention to safety

Safety features are still a priority while developing laser cutting tables for steel. New safety regulations and sensor systems are putting in laser cutting tables to prevent possible accidents and protect workers from dangers exposed to laser.

IV. The Future of Laser Cutting Tables for Steel

As we make great progress in 2025, the best-selling laser cutting tables in China are ready to shape the future of steel fabrication. Due to innovations in laser technology, automation, energy-saving and user-friendly control systems, the Chinese manufacturers are setting a higher standard for global markets. Whether you’re looking for a cutting-edge machine for a large-batch industrial operation or an all-purpose solution for smaller tasks, the laser cutting tables available in China are sure to support your demands.