This right-angled cutting head can take accurate control of its swing angle and monitor its gas flow output in real time. As thus, the gas flow will concentrate on metal surface to make beveling section better.

- Autofocus

- Auto obstacle avoidance

- Smart temperature/gas leakage detection

Intelligent bus-based CNC system is outfitted with content-rich cutting database that offers a wealth of crafts. Automatic nesting software is also available to enable quality cutting of common and special-shaped tubes.

* Auto center search * Eccentricity compensation * Co-edge cutting

* Corner cutting * Drawing imports in batch * Auto plotting

* Cutting path editing * Welds compensation

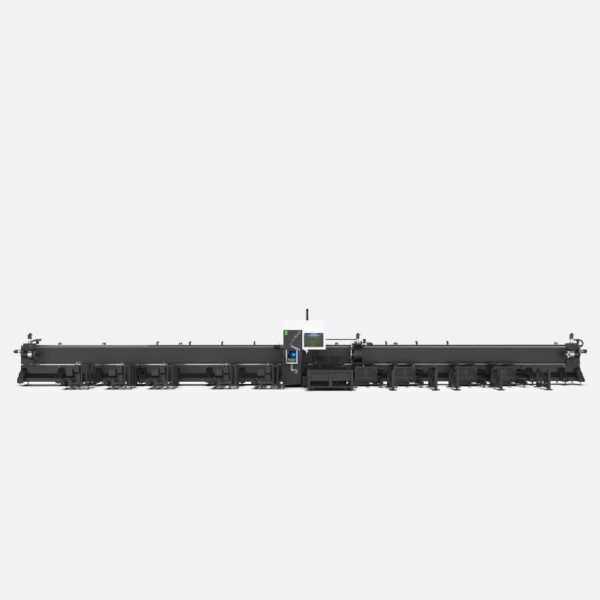

The machine comes standard with turning plate as unloading device to unload 3m long tube. Users may apply for semi-/fully-automatic loading devices as optional accessories, so as to reduce labor intensity during work.

- Servo control

Avoid tube sagging’s effect on cutting precision

- Automatic separation

Separate scraps and finished products automatically with no manual intervention

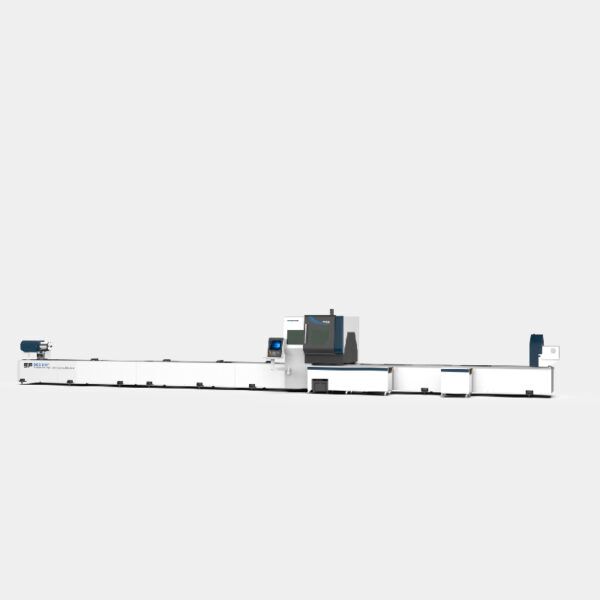

The self-centering chucks can clamp tubes at constant but adjustable clamping force. Large tube is clamped stably and small tube will remain unchanged in shape.

- Auto obstacle avoidance

- Short tailing

- Dust-proof seal structure

- Auto removal of cuttings

The support is servo-controlled and move along with rotating tube by clinging to its surface. It is designed as segmented, so tube will not shake while being cut at fast speed. In this way, precision is not affected by long tube sagging.

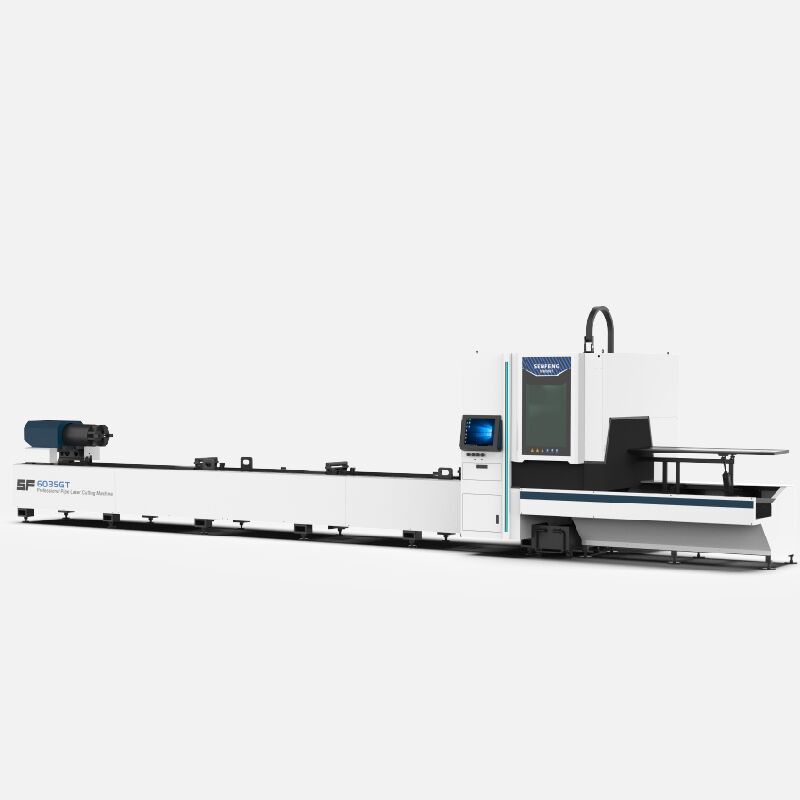

| Model | SF6035GT |

| Laser Power (kW) | 3-6 |

| Max Length of Tube (mm) | 6000 |

| Scope of Tube Size (mm) | Φ50~360 |

| □50*50~360*360 | |

| Max Weight of Tube (kg) | 700 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.03 |

| Max No-load Speed (m/min) | 60 |

| Max Rotating Speed of Chucks (r/min) | 60 |

| Overall Dimensions (L*W*H, mm) | 10200*2280*2530 |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) |

HERE ARE YOUR ANSWERS

Free on-site Demo

Contact the showroom in advance and come

to SENFENG to enjoy silky cutting at any time.

Call or Chat

Don’t know how to solve the problem you encounter?

We are always here!

Call (562) 319 8053

Reviews

There are no reviews yet.