Column spacing (B-axis) After countless experiments and deduction, SENFENG team designed the most suitable column spacing for different models to achieve high-strength and high-precision bending.

Mechanical crowning (V–axis) is added to SENFENG machines to compensate for any deflection or deformation, ensuring that the workpiece is bent accurately and consistently across its entire length.

4 Back gauge fingers The fastest speed of the X-axis is as high as 500mm/s, which is 1.5 times the speed of the same industry.

German REXROTH hydraulic system is known for its durability and reliability, which is designed to withstand harsh conditions and heavy use, ensuring long-lasting performance and productivity.

DSP laser safety protection device is an important safety feature in a CNC bending machine, helping to protect the operator and improve the overall safety and compliance of the machine.

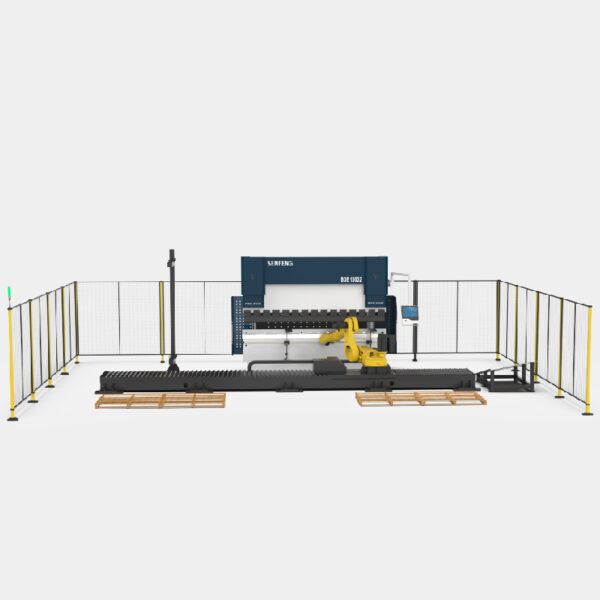

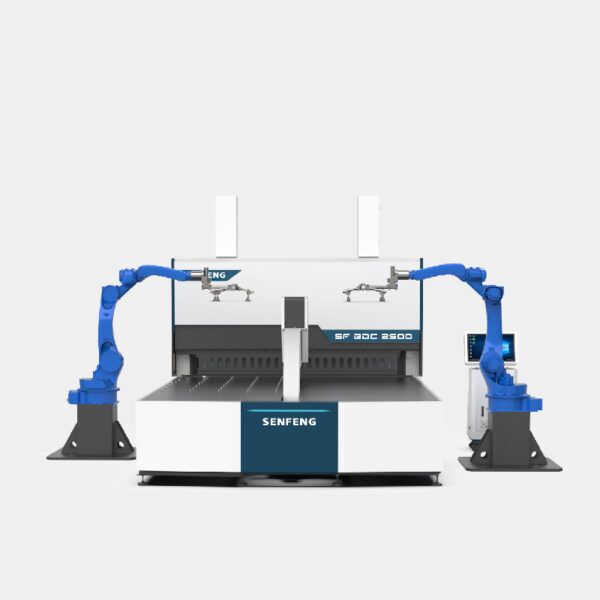

Robotic feeding cell can also be used for automatic feeding of sheet metal, which improves productivity and reduces downtime, and realizes high-precision bending with automation and flexibility.

| Model | BDE5016 | BDE10032 | BDE10042 | BDE13032 | BDE20060 | BDE25032 | BDE60060 | |

| Bending Force (kN) | 500 | 1000 | 1000 | 1300 | 2000 | 2500 | 6000 | |

| Bending Length (mm) | 1600 | 3200 | 4200 | 3200 | 6000 | 3200 | 6000 | |

| Depth of Throat (mm) | 205 | 400 | 400 | 400 | 400 | 400 | 600 | |

| Width Between Columns (mm) | 1200 | 2600 | 3600 | 2600 | 5000 | 2600 | 4800 | |

| Open Height (mm) | 460 | 480 | 480 | 480 | 480 | 500 | 670 | |

| Speed of Slide Blocks (mm/s) | Approach | 180 | 180 | 180 | 180 | 140 | 130 | 90 |

| Bend | 0-10 | 0-10 | 0-10 | 0-10 | 0-8 | 0-8 | 0-7 | |

| Return | 160 | 160 | 160 | 160 | 110 | 120 | 90 | |

| Overall Dimensions (L*W*H, mm) | 2100*1770*2395 | 3700*1930*2630 | 4700*1930*2630 | 3700*1930*2630 | 6500*2150*3290 | 3700*2120*2800 | 6200*2700*4750 | |

| Machine Weight (kg) | 3400 | 6600 | 8300 | 8120 | 18500 | 10300 | 52000 | |

| Main Motor Power (kw) | 5.5 | 7.5 | 7.5 | 11 | 18.5 | 18.5 | 45 | |

HERE ARE YOUR ANSWERS

Free on-site Demo

Contact the showroom in advance and come

to SENFENG to enjoy silky cutting at any time.

Call or Chat

Don’t know how to solve the problem you encounter?

We are always here!

Call (562) 319 8053

Reviews

There are no reviews yet.