Introduction

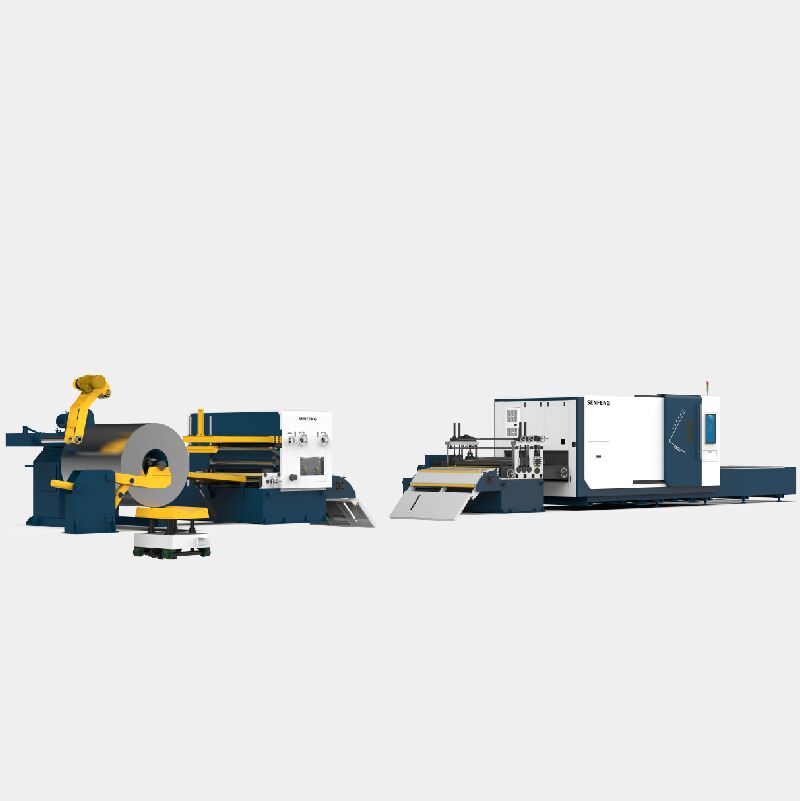

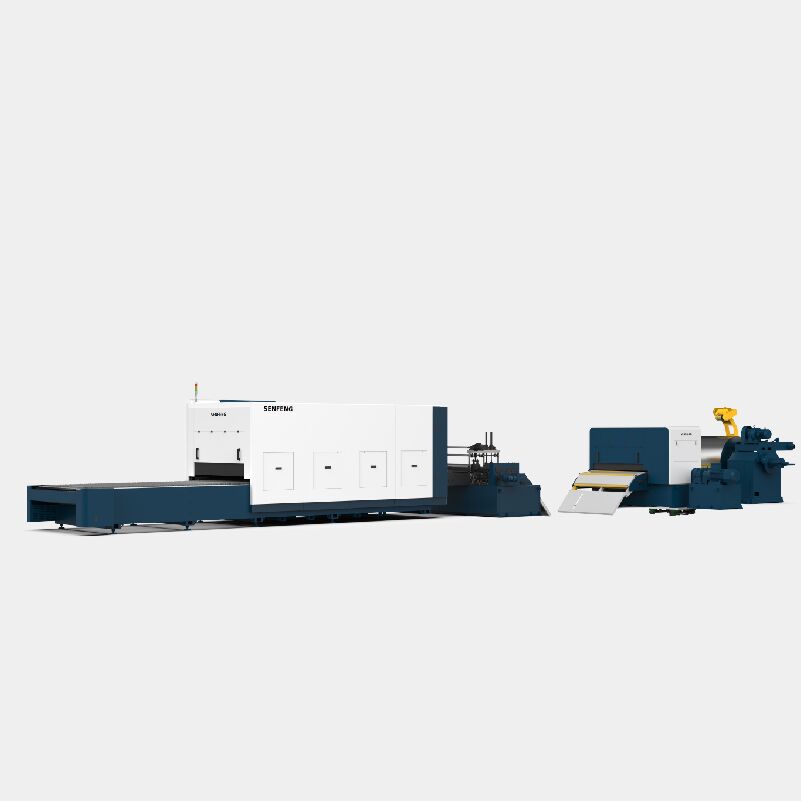

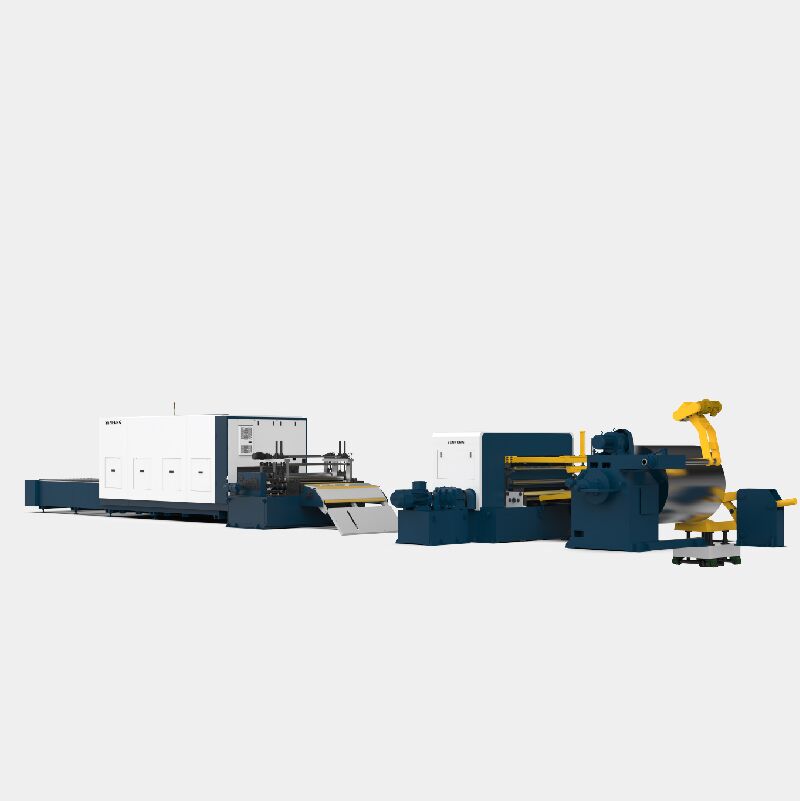

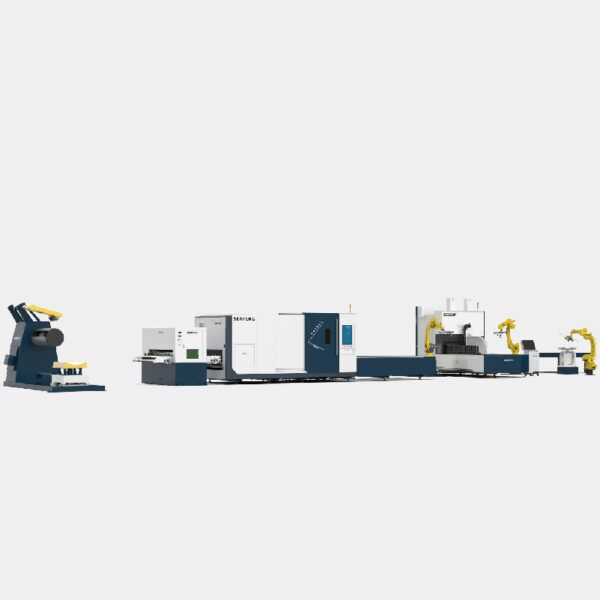

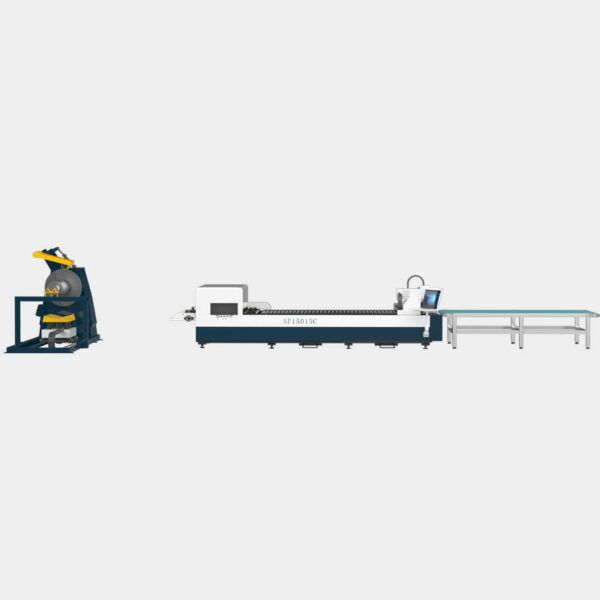

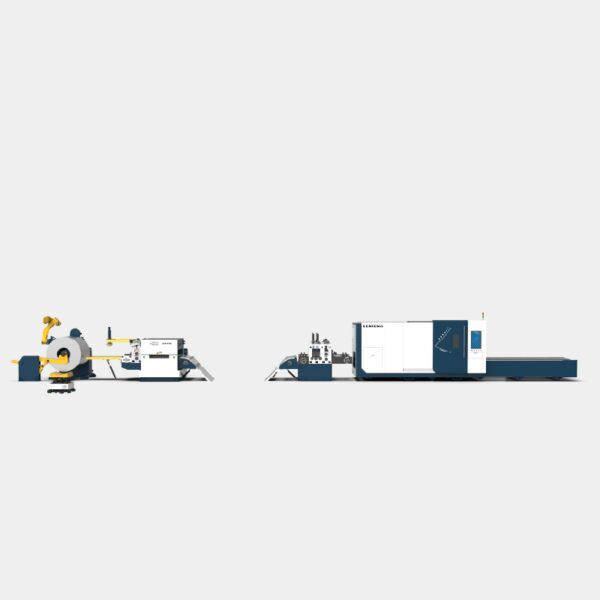

Rolled steel cutting machine is composed of a feeding trolley, a single support uncoiler, auxiliary support, a feeding mechanism, a leveling feeder, a sheet metal positioning and correction device, a laser cutting unit, and an electronic control system. The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

The Video of Rolled Steel Fiber Laser Cutter

Check out the videos below to take a closer look at the beauty and power of the rolled steel fiber laser cutter

Technical Parameters of Coil Fed Fiber Laser Cutting Machine SF1503CH

| Model | 1503CH | |

| Decoiling and Leveling Unit | Size of Sheet Coil (L*W*T) | 118.11″ * 59.06″ * 3 |

| Standard inner diameter of sheet coil | Φ20″ | |

| Max outer diameter of sheet coil | Φ55.12″ | |

| Weight of Sheet Coil (T) | 10 | |

| Max Feeding Speed | 393″/min | |

| Leveling Accuracy (mm/m²) | ±2 | |

| Laser Cutting Machine | Laser Power (kW) | 1.5-6 |

| Working Area (L*W) | 118.11″ * 59.06″ | |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 | |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | |

Main Features of Rolled Steel Laser Cutter

1. Stepless Speed Regulation

The support roller is driven to rotate by the geared motor through the sprocket strip, and always keeps the plate between the uncoiling and feeding in the suspended state, and the speed reaches 393″/min, in order to achieve the preparation for stress relief. And the load-bearing capacity of the single-support uncoiler is 22000 lbs.

2.Ultra-Precision Correction Technology

A special lead screw nut is used to drive the correcting roller to install the sliding block, so that the correcting tube wheel can straighten the plate, realize the guiding positioning of the plate, prevent the plate from being scratched during the movement process, and accurately position the plate without laser edge seeking, saving the time of plate cutting.3.Extremely Fast Stress Relief Technology

After the coil is uncoiled, while the flat material is leveled by the leveling machine, the internal stress of the plate can be released in advance, making the plate smoother, and the excellent laser cutting experience and efficiency have never been obtained.Cutting Samples

Application

This product is mainly used in the cutting field of thin stainless steel materials and industries where the thickness of the product is relatively single. For example, automotive sheet metal parts, aluminum veneer, electrical cabinets, metal door industry, kitchen utensils industry, equipment sheet metal, etc.Five Star Fast Service System

1.High efficiency

- 24 hours a day (mainly for international), 7 days a week, 365 days a year at any time to receive repair calls;

- Within 10 minutes, technical engineers will consult, fix maintenance plan in one hour, and send engineers in one working day.

2.After-sale service

- The seller provides one time free installation and training in buyer’s factory. Seller pays for the airplane tickets and salary for engineers, buyer should provide accommodation and food to engineers.

- The seller will provide technical guide’s e-mail, telephone, WeChat, WhatsApp and so on.

- The seller should pay for the travel expense if local service needed within warranty time.

3.Warranty

- The warranty of laser source is 2 years.

- The warranty of the machine is 2 years(main spare parts),except for the consumable parts such as ceramic ring, focus lens, nozzle etc. Warranty counts from the date marked on the label of the laser source and machine.

- Except the damage artificially, seller is responsible for offering the fittings free of charge during the warranty period.

4.Worry-free

- Pre-sale service: theoretical + practical operation training, self-diagnosis training for common faults, guidance for quick repair of difficult faults, and warning of matters needing attention in use;

- Regular service: regular maintenance reminder, regular door-to-door service, regular promotional activities;

- Value-added services: equipment software and hardware upgrading services, financial leasing services, delayed warranty service.

For more details, welcome to contact us! CLICK HERE!

LOCAL SERVICE

Our North American Tech/Demo Center is located in the Los Angeles Industrial Region, conveniently near the Port of LA.

1) Equipped with showroom, sales manager, engineers and machine.

2) Price, stateside Tech-Support, Components, Capabilities, and Warranty that is likewise protected under USA Trade Law, as most of our competitors do not have USA Legal or Tech presence as we do.

PRE SALE SERVICE

1) Provide corresponding guidance and equipment information according to customer’s development needs;

2) Solve problems based on the feasibility and development requirements of local market;

3) Provide large-scale optical fiber equipment exhibition hall for customers to confirm the strength of our company.

AFTER-SALE SERVICE

1) The seller provides one-time free installation and training service at buyer’s factory, as well as the airplane tickets and salary for engineers. The buyer should provide accommodation and food to engineers.

2) The seller provides technical guide’s e-mail, telephone, Wechat, Whatsapp and so on.

3) The seller shall pay for the travel expense if local service needed within warranty time.OUR FACTORY

SENFENG LASER is a professional sheet metal fiber laser cutter manufacturer engaged in the research, development, production, sale and service of fiber laser cutting machine, fiber laser cleaning machine, laser marking machine, laser welding machine and 3D robot. Our laser cutting machine has successfully passed CE from TUV, FDA, ISO9001-2015 certification. SENFENG LASER has established 2 subsidiaries in the United States, and Germany and 4 service centers in India, Pakistan, Serbia , and Vietnam with perfect quality and service, to provide localized services and technical support for global customers.

Reviews

There are no reviews yet.