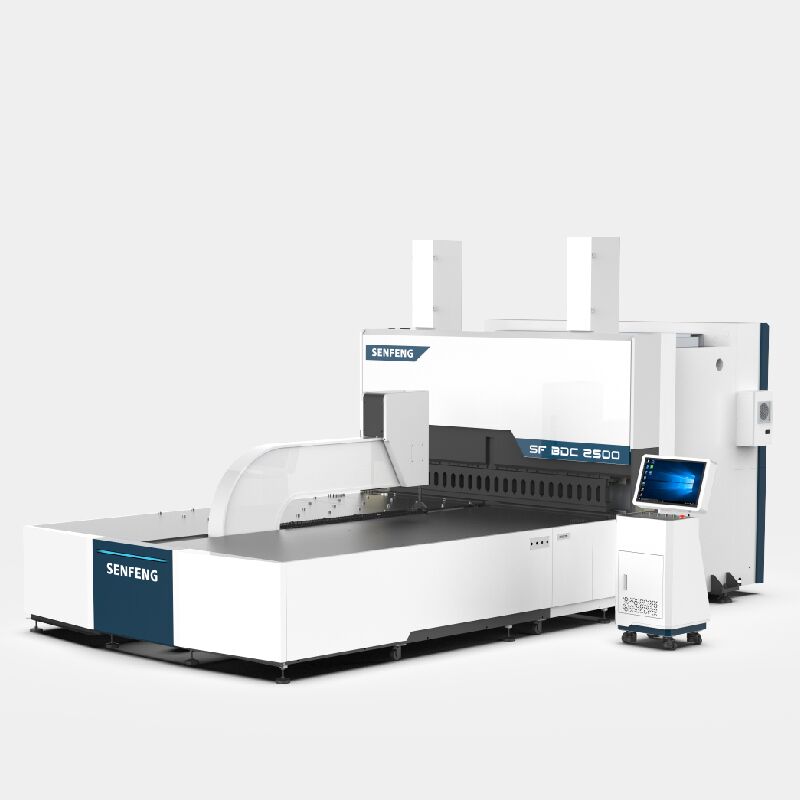

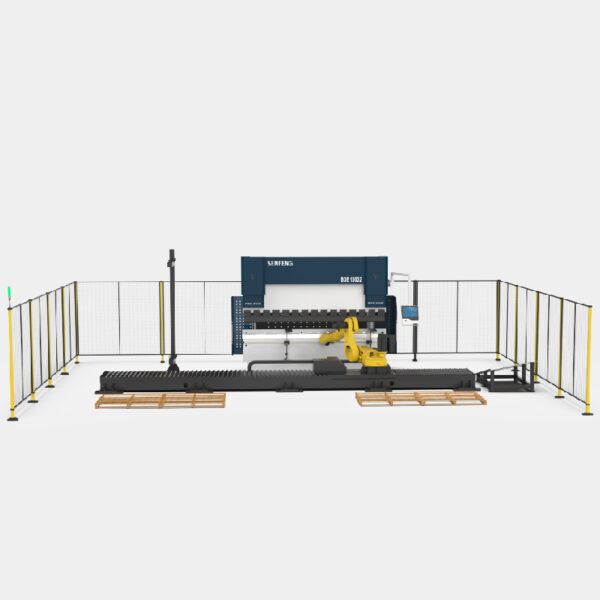

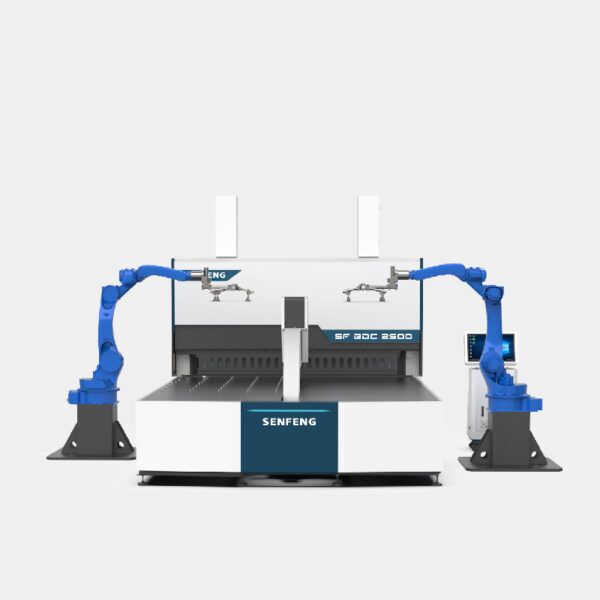

It is designed for high-volume production running with a higher level of automation and features such as universal bending tools and automatic feeding systems, which reduces manual labor and increases efficiency.

BDC Series can easily realize basic bending styles such as right angle, acute angle, obtuse angle, etc., and can also realize arc, dead edge, return type, closed type, and other complex sheet metal bending requirements.

It can adapt to the bending of workpieces with different angles and radii to meet changing production needs, reduce downtime and increase productivity.

The main difference is the way in which the sheet metal is held in place during the bending process.

Vacuum suction bending is best suited for thin and delicate sheet metal materials that require high precision and accuracy, while downward bending is best suited for thicker and more robust sheet metal materials that require a higher level of force and a consistent bend angle.

EtherCAT is a high-performance, real-time Ethernet-based fieldbus system that is widely used in industrial automation applications, including bending machines.

High-speed communication

Ideal for complex bending applications

Improved synchronization

Enhanced diagnostic capabilities

| Model | BDC1500 | BDC2000 | BDC2500 | BDC3200 |

| Max Bending Speed (S/bend) | 0.2 | 0.2 | 0.2 | 0.2 |

| Max Bending Length | 59.06″ | 78.74″ | 98.43″ | 125.98″ |

| Max Bending Thickness (mm) | 304 stainless steel: 1.5 | 304 stainless steel: 1.5 | 304 stainless steel: 1.5 | 304 stainless steel: 1.5 |

| cold plate: 2.0 | cold plate: 2.0 | cold plate: 2.0 | cold plate: 2.0 | |

| AL sheet: 2.5 | AL sheet: 2.5 | AL sheet: 2.5 | AL sheet: 2.5 | |

| Min Bending Thickness (mm) | 0.35 | 0.35 | 0.35 | 0.35 |

| Max Bending Size (L*W) | 59.06″*49.21″ | 78.74″*49.21″ | 98.43″*49.21″ | 125.98″*49.21″ |

| Number of Axes | 13-axis concurrent linkage | 13-axis concurrent linkage | 13-axis concurrent linkage | 16-axis concurrent linkage |

| Rated Voltage (V) | 380 | 380 | 380 | 380 |

| Total Motor Power (KW) | 34.2 | 36.5 | 65 | 80 |

| Overall Dimensions (L*W*H, mm) | 4400*2000*2750 | 5000*2700*2950 | 5700*3200*3050 | 6600*4000*3280 |

| Gross Mass (T) | 13 | 17 | 22 | 25 |

HERE ARE YOUR ANSWERS

Free on-site Demo

Contact the showroom in advance and come

to SENFENG to enjoy silky cutting at any time.

Call or Chat

Don’t know how to solve the problem you encounter?

We are always here!

Call (562) 319 8053

Reviews

There are no reviews yet.